Proper maintenance of slaughtering equipment is essential for ensuring efficiency, safety, and longevity in meat processing operations. Slaughterhouses rely on specialized machinery to handle tasks such as stunning, bleeding, evisceration, and carcass handling. Without regular upkeep, equipment can malfunction, leading to costly downtime, reduced productivity, and potential safety hazards. Implementing a structured maintenance routine helps facilities operate smoothly while maintaining high standards of hygiene and product quality.

Importance of Regular Maintenance

Regular maintenance of slaughtering equipment ensures that machines operate at peak performance. Consistent upkeep minimizes the risk of unexpected breakdowns, reduces repair costs, and extends the lifespan of the machinery. Neglecting maintenance can result in decreased efficiency, increased energy consumption, and potential contamination if equipment surfaces or components degrade over time. For businesses aiming to improve operational efficiency, investing in high-quality slaughtering equipment and following a strict maintenance schedule is crucial to sustaining long-term productivity and safety.

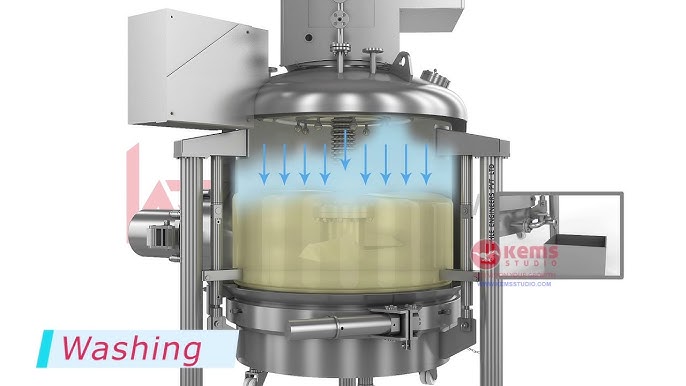

Daily Cleaning and Sanitation

One of the most important maintenance practices is daily cleaning and sanitation. Slaughtering equipment comes into direct contact with blood, fat, and other organic materials, which can harbor bacteria if not removed promptly. Machines should be disassembled as needed and washed using appropriate cleaning agents and sanitizers approved for food processing equipment. Stainless steel surfaces, removable components, and smooth designs facilitate easier cleaning. Proper cleaning not only maintains hygiene standards but also prevents corrosion, wear, and mechanical issues, ensuring the machinery functions efficiently.

Lubrication and Moving Parts Care

Proper lubrication of moving parts is essential to prevent wear and tear on critical components. Bearings, chains, gears, and conveyor systems require regular application of food-grade lubricants to reduce friction and avoid overheating. Failure to lubricate can cause machinery to operate inefficiently, produce excessive noise, and lead to premature breakdowns. Scheduling routine lubrication as part of a maintenance plan ensures smooth operation, prolongs equipment lifespan, and enhances overall productivity.

Inspection and Component Replacement

Routine inspections are necessary to identify potential issues before they escalate into major problems. Operators and maintenance personnel should check for signs of wear, corrosion, loose bolts, damaged blades, or malfunctioning sensors. Worn or damaged components should be replaced promptly to avoid operational interruptions. Maintaining an inventory of essential spare parts allows for quick replacements and reduces downtime. Regular inspections also help facilities comply with safety regulations and maintain consistent meat quality.

Calibration and Adjustment

Many slaughtering machines require precise calibration to ensure accurate cutting, portioning, and processing. Regularly checking and adjusting machinery helps maintain precision, reduces wastage, and ensures uniformity across all processed products. Calibration is particularly important for automated or computerized equipment, where minor deviations can affect productivity and product quality. Incorporating calibration checks into the maintenance schedule allows facilities to operate efficiently and meet production targets consistently.

Electrical Systems Maintenance

Electrical components are critical to the performance of modern slaughtering equipment. Motors, wiring, sensors, and control panels should be inspected regularly for signs of wear, overheating, or damage. Loose connections or faulty wiring can result in unexpected downtime or safety hazards. Proper maintenance of electrical systems, including cleaning dust accumulation and testing safety circuits, ensures reliable performance and reduces the risk of fire or mechanical failure. Engaging qualified electricians for periodic inspections can further enhance safety and efficiency.

Documentation and Maintenance Records

Keeping detailed records of all maintenance activities is essential for effective equipment management. Documentation should include cleaning schedules, lubrication logs, inspections, component replacements, and any repairs performed. Maintaining a comprehensive history helps operators identify recurring issues, plan preventive maintenance, and comply with regulatory audits. Proper record-keeping also allows management to assess equipment performance and make informed decisions regarding upgrades or replacements.

Training for Maintenance Personnel

The effectiveness of a maintenance program depends on the skill and knowledge of the personnel performing it. Maintenance staff should receive proper training on equipment operation, cleaning procedures, lubrication requirements, safety protocols, and troubleshooting techniques. Well-trained personnel can identify potential issues early, perform tasks correctly, and maintain the equipment in optimal condition. Continuous training ensures that the team stays updated with technological advancements and best practices in slaughterhouse maintenance.

Conclusion

Regular maintenance of slaughtering equipment is vital for sustaining efficiency, safety, and product quality in meat processing operations. Key practices include daily cleaning, proper lubrication, routine inspections, calibration, electrical system care, record-keeping, and staff training. By implementing a structured maintenance plan, slaughterhouses can prevent unexpected breakdowns, reduce operational costs, and extend the lifespan of their machinery. Prioritizing maintenance ensures smooth workflow, compliance with hygiene and safety standards, and consistent production output, making it a cornerstone of successful and sustainable meat processing operations.