Sustainability has become a key focus in modern manufacturing, driving demand for environmentally friendly packaging solutions. One technology that has gained significant attention is water soluble film packaging. These films dissolve completely in water, offering a convenient, eco-friendly alternative to traditional plastic packaging. Water soluble film packaging machines play a vital role in producing these sustainable packages efficiently and consistently. By integrating automation, precision, and environmental considerations, these machines help manufacturers reduce waste, improve product safety, and meet consumer demand for sustainable products.

Reducing Plastic Waste

One of the most significant benefits of using water soluble film packaging machines is the reduction of plastic waste. Conventional packaging often relies on single-use plastics, which contribute heavily to environmental pollution and landfill accumulation. Water soluble films, in contrast, dissolve entirely in water, leaving no harmful residues behind.

Industrial and consumer products such as detergents, cleaning chemicals, and single-dose pharmaceuticals benefit greatly from this approach. By packaging products in water soluble films, manufacturers can eliminate the need for additional plastic containers or wrappers. The result is a reduction in material usage, lower disposal costs, and a smaller environmental footprint. This makes water soluble film packaging an attractive option for companies seeking to adopt greener practices.

Precision and Consistency in Packaging

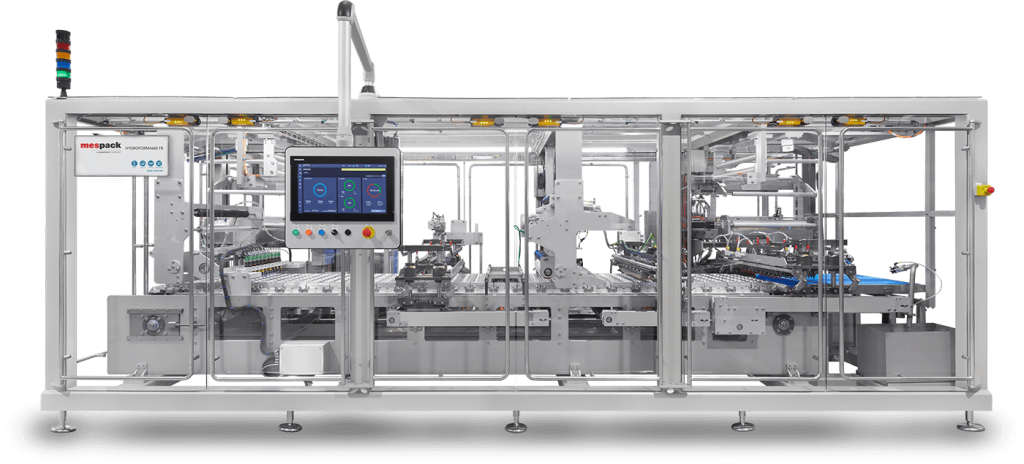

A high-quality Water Soluble Film Packaging Machine ensures precise and consistent packaging, which is essential for both sustainability and efficiency. These machines automate the processes of film feeding, forming, filling, sealing, and cutting, minimizing human error and material wastage. Precise dosing prevents overuse of chemicals or active ingredients, reducing product waste and ensuring that each package delivers the intended performance.

Automation also contributes to sustainability by optimizing film usage. By controlling tension, alignment, and sealing pressure, these machines minimize scrap and prevent damaged or misaligned packages. Less material waste means fewer resources are consumed, supporting both cost efficiency and environmental goals. For large-scale production, this precision translates into significant savings and a measurable reduction in overall ecological impact.

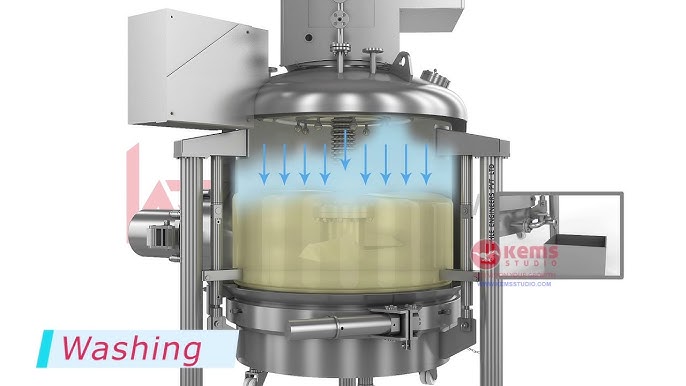

Hygiene and Safety Benefits

Sustainable packaging is not only about environmental impact but also about reducing contamination and ensuring product safety. Water soluble film packaging machines offer high levels of hygiene, as automated systems reduce human contact with products. This is particularly important for pharmaceuticals, healthcare products, and concentrated chemicals, where contamination could compromise effectiveness or safety.

Enclosed machine designs, stainless steel construction, and easy-to-clean components maintain sanitary conditions during production. By preventing contamination, manufacturers can reduce product recalls and waste, further supporting sustainability. High hygiene standards also align with regulatory compliance requirements, ensuring that eco-friendly packaging does not come at the cost of product safety.

Versatility Across Industries

Water soluble film packaging machines are versatile and suitable for a wide range of industries. In the detergent and cleaning sector, they produce single-dose pods, capsules, and sachets that are convenient for consumers and reduce excess packaging. In pharmaceuticals and healthcare, they allow precise dosing of powders, gels, and liquids in single-use formats that enhance patient safety. Even industrial applications benefit from pre-measured chemical packets that prevent overuse and reduce environmental hazards.

This versatility means manufacturers can adopt sustainable packaging across multiple product lines without the need for different machines or extensive production modifications. Standardized, automated processes improve efficiency while minimizing material and energy consumption, further reinforcing eco-friendly manufacturing practices.

High-Speed Production with Sustainability

Modern water soluble film packaging machines are designed for high-speed production without compromising sustainability. Multi-lane configurations and automated controls allow simultaneous packaging of multiple units, increasing output while maintaining precision. Energy-efficient motors, optimized heating systems, and advanced dosing mechanisms reduce power consumption and material waste.

High-speed automation ensures that even large-scale operations can produce environmentally friendly packaging efficiently. This allows manufacturers to meet growing market demand for sustainable products while keeping production costs under control. In this way, water soluble film packaging machines combine economic and ecological benefits.

Maintenance and Operational Considerations

Proper maintenance is crucial to maximize the sustainability benefits of water soluble film packaging machines. Regular cleaning of rollers, molds, and sealing components prevents film residue buildup and maintains operational efficiency. Monitoring environmental conditions such as humidity and temperature ensures the films remain intact during production, minimizing waste. Operator training in machine handling and preventive maintenance further enhances performance, reduces downtime, and ensures consistent production quality.

Conclusion

Water soluble film packaging machines provide an effective solution for manufacturers seeking to implement sustainable packaging practices. By reducing plastic waste, improving dosing precision, enhancing hygiene, and supporting high-speed production, these machines contribute significantly to eco-friendly manufacturing. Their versatility allows use across multiple industries, from detergents and cleaning products to pharmaceuticals and healthcare, while maintaining efficiency and product quality. With proper maintenance and optimized operation, water soluble film packaging machines help companies achieve sustainability goals, reduce environmental impact, and meet consumer expectations for responsible packaging solutions.