Agitated Nutsche Filter Dryers (ANFDs) are critical in the chemical, pharmaceutical, and fine chemical industries due to their ability to perform filtration, washing, and drying in a single, enclosed vessel. Over the years, manufacturers have continuously innovated ANFD designs to enhance efficiency, safety, and product quality. These innovations address the evolving demands of modern industries, including handling sensitive materials, meeting regulatory standards, and optimizing production processes.

An Agitated Nutsche Filter Dryer Manufacturer plays a key role in developing these advanced solutions. Leading manufacturers incorporate new technologies, materials, and automation features to deliver high-performance systems tailored to specific industrial requirements. For industrial-grade options and detailed specifications, you can explore this Agitated Nutsche Filter Dryer Manufacturer, recognized for integrating cutting-edge innovations into their equipment.

Advanced Agitator Designs

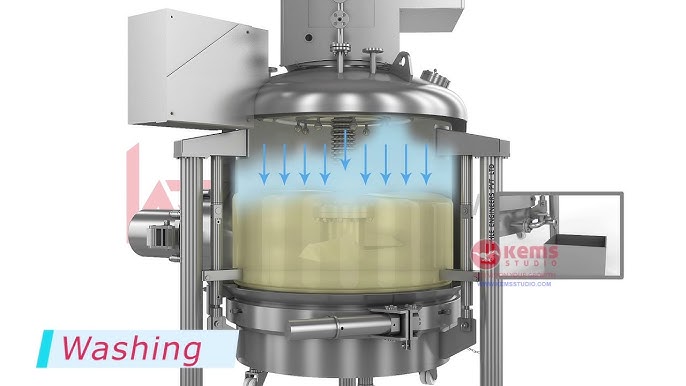

One of the most significant innovations in ANFDs is the development of advanced agitator designs. Traditional agitators often faced challenges such as uneven mixing, cake formation, or mechanical wear. Modern designs, including plough, paddle, and anchor agitators, have been optimized to ensure uniform mixing of solids, prevent caking, and facilitate efficient washing and drying.

Innovative agitators are now designed to handle high-viscosity slurries, abrasive solids, and temperature-sensitive materials. Adjustable blade configurations and variable-speed drives allow precise control of agitation intensity, minimizing mechanical stress on the product while improving process efficiency. These enhancements reduce downtime, extend equipment life, and ensure consistent product quality across batches.

Integration of Automation and Process Control

Automation is a major focus of recent innovations. Manufacturers have introduced sophisticated control systems that monitor and regulate key process parameters such as temperature, vacuum pressure, and agitation speed. Real-time data acquisition and feedback systems enable operators to optimize filtration, washing, and drying cycles automatically.

Advanced ANFDs may include programmable logic controllers (PLCs) and touchscreen interfaces that allow precise adjustments for different materials and batch sizes. Automation not only reduces human error but also enhances reproducibility and process efficiency, which is particularly important in pharmaceutical production where consistent quality is critical.

Material and Coating Advancements

Innovations in material selection and surface coatings have improved the durability and chemical resistance of ANFDs. While stainless steel remains standard, manufacturers now offer high-performance alloys like Hastelloy, titanium, and duplex stainless steel for highly corrosive or aggressive chemicals.

In addition, specialized surface coatings and finishes, including electropolishing and passivation, enhance corrosion resistance and ease of cleaning. These improvements support compliance with cGMP and other regulatory standards while ensuring longevity and reducing maintenance requirements. By minimizing corrosion and residue buildup, these innovations also help maintain product purity and operational efficiency.

Enhanced Safety Features

Safety is a critical concern in chemical and pharmaceutical processing. ANFD manufacturers have introduced innovations such as explosion-proof motors, inert gas purging, and advanced pressure relief systems to protect operators and equipment. Modern vessels are designed with improved seals, vacuum integrity, and interlocks to prevent leaks and exposure to hazardous materials.

Some innovations also include automated emergency shutdown systems and real-time monitoring of potential hazards, such as pressure spikes or overheating. These features minimize the risk of accidents and ensure compliance with increasingly stringent industrial safety regulations.

Efficient Heating and Drying Technologies

Energy efficiency is another area where innovations have transformed ANFD performance. Improved heating jackets, filter plate designs, and vacuum-assisted drying systems allow for uniform and controlled heat distribution, enabling faster drying cycles at lower energy consumption.

Innovative designs include multi-zone heating and modular heating circuits that adapt to the specific thermal needs of different materials. These features reduce energy costs while maintaining product integrity, particularly for heat-sensitive compounds in pharmaceutical and fine chemical applications.

Customization and Modular Designs

Modern manufacturers offer modular ANFD designs that allow clients to tailor equipment for specific processes and products. Customizable vessel sizes, agitator types, filtration media, and discharge mechanisms enable manufacturers to handle a wide variety of materials and batch volumes efficiently.

Modular designs also facilitate easier maintenance, component replacement, and scale-up for increased production capacity. By offering flexible and adaptive equipment, manufacturers help clients achieve optimal performance while minimizing downtime and operational costs.

Conclusion

Agitated Nutsche Filter Dryer manufacturers have introduced numerous innovations that enhance performance, efficiency, and safety. Advanced agitator designs, automated process controls, material and coating improvements, safety enhancements, efficient heating systems, and customizable modular designs have transformed ANFDs into highly versatile and reliable tools for modern chemical, pharmaceutical, and fine chemical production.

These innovations ensure consistent product quality, reduce downtime, and improve operational efficiency while maintaining compliance with stringent regulatory and safety standards. By choosing a manufacturer that incorporates these innovations, companies can optimize their batch processing operations, achieve superior product outcomes, and maintain a competitive edge in their industry.