Power press machines are widely used in manufacturing industries for metal forming, punching, stamping, and bending operations. These machines offer precision, speed, and efficiency, making them essential in automotive, electronics, appliance, and construction sectors. Choosing the right type of power press is critical for ensuring consistent quality, productivity, and safety in the production process. Manufacturers produce various types of power press machines to meet different operational requirements, material types, and production volumes.

A reliable Power Press Machine is designed to cater to specific manufacturing needs by providing controlled force, precision movement, and repeatable operations. These machines are classified based on their driving mechanism, operational method, and intended application. Understanding the types of power press machines available allows manufacturers and operators to select the equipment that best suits their production demands, reduces waste, and improves overall efficiency.

Mechanical Power Press Machines

Mechanical power press machines are among the most commonly used types in manufacturing. These presses utilize a flywheel that stores energy, which is then transferred to the ram through a crankshaft or linkage system. Mechanical presses are ideal for high-speed operations, such as blanking, piercing, and forming metal sheets in large production runs.

C-frame and H-frame designs are typical for mechanical presses. C-frame presses provide easy access to the work area and are suitable for small to medium-sized parts, while H-frame presses offer greater structural strength and stability, making them suitable for heavy-duty operations. Mechanical presses are valued for their speed and efficiency, but they offer less flexibility in stroke length and force adjustment compared to hydraulic presses.

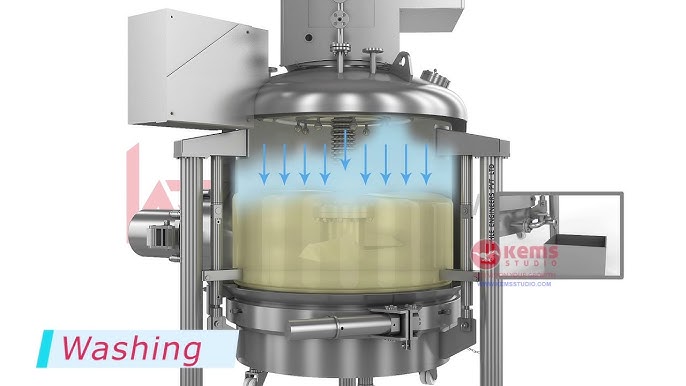

Hydraulic Power Press Machines

Hydraulic power press machines operate using hydraulic cylinders to generate force, allowing greater control over speed, pressure, and stroke length. These machines are suitable for operations that require high precision or involve thick and hard materials. Hydraulic presses are commonly used for deep drawing, forging, and complex metal forming tasks.

The advantages of hydraulic presses include adjustable tonnage, uniform force distribution, and longer stroke lengths. They are ideal for applications where flexibility, accuracy, and consistency are critical. Additionally, hydraulic presses often feature programmable settings that allow operators to customize force and speed for different materials and product specifications, ensuring minimal waste and higher quality output.

Pneumatic Power Press Machines

Pneumatic power press machines use compressed air to drive the ram. These machines are generally suitable for light-duty applications such as assembly, small punching operations, and moderate metal forming tasks. Pneumatic presses offer fast operation, low maintenance, and energy efficiency, making them ideal for small to medium-scale manufacturing environments.

While they are not suitable for heavy-duty operations due to limited force capacity, pneumatic presses are cost-effective, easy to operate, and provide consistent performance for lightweight materials. Their simple design and operational flexibility make them a popular choice for small workshops or production lines that require moderate precision.

Servo-Driven Power Press Machines

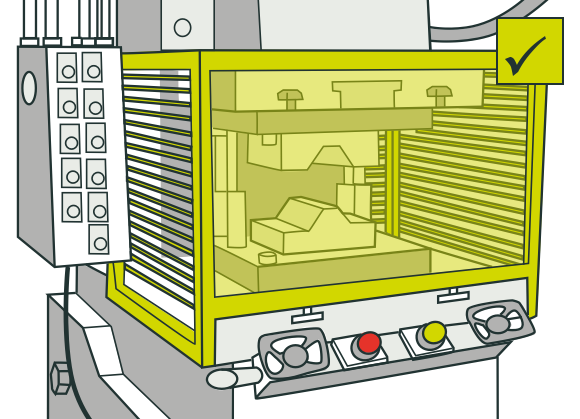

Servo-driven power press machines are a modern advancement that offers high precision and adaptability. These presses use servo motors to control ram movement, allowing variable stroke speed, position, and force. This level of control makes them suitable for complex operations that require consistent accuracy and minimal material deformation.

Servo-driven presses are commonly used in electronics, automotive, and high-precision metal forming applications. Their programmability allows manufacturers to optimize the forming process for different materials and part designs, reducing production errors and improving efficiency.

Mechanical-Hydraulic Hybrid Press Machines

Some manufacturers offer hybrid presses that combine the speed of mechanical presses with the flexibility of hydraulic systems. These machines utilize mechanical components for high-speed operation while incorporating hydraulic control for adjustable force and stroke. Hybrid presses provide the best of both worlds, offering efficient production with precise control and energy savings.

Hybrid presses are ideal for high-volume operations that also require occasional adjustments for different part types or materials. They are often used in automotive and appliance manufacturing, where both speed and accuracy are essential.

Conclusion

Power press machines come in various types to meet the diverse needs of modern manufacturing. Mechanical presses provide speed for high-volume production, hydraulic presses offer precision and flexibility, pneumatic presses are suitable for light-duty tasks, servo-driven presses deliver high accuracy for complex operations, and hybrid presses combine speed and control for versatile applications. A well-chosen Power Press Machine ensures reliable performance, efficient production, and consistent quality. Understanding the differences between these types allows manufacturers to select the right equipment, optimize workflows, and maintain safety and precision in their operations.