In today’s fast-growing laundry care market, manufacturers are under pressure to produce high-quality detergent pods efficiently while minimizing waste and reducing operational costs. Traditional manual production methods are labor-intensive, slow, and prone to inconsistencies, making them unsuitable for large-scale operations. Detergent pod making machines have transformed this process by integrating automation, precision control, and innovative engineering, significantly improving production efficiency and ensuring consistent product quality.

Streamlined Automated Production

One of the primary ways detergent pod making machines enhance efficiency is through automation. These machines handle multiple stages of pod production, including film feeding, detergent dosing, sealing, and cutting, in a seamless, continuous process.

Machines like the Detergent Pod Making Machine integrate advanced programmable logic controllers (PLC) and human-machine interfaces (HMI) to monitor and control production parameters in real time. Automation reduces the reliance on manual labor, minimizes human error, and allows for consistent pod quality across high-volume production runs. By streamlining operations, manufacturers can increase output without compromising precision, ensuring that each pod meets strict quality standards.

Accurate Dosing and Consistent Quality

Efficiency in detergent pod production is closely linked to accurate dosing. Precise measurement of detergent formulations—whether liquid, gel, or powder—prevents underfilling or overfilling pods, reducing material waste and improving cleaning performance.

Modern detergent pod making machines are equipped with advanced dosing systems, including piston pumps, volumetric fillers, and auger mechanisms, which deliver exact quantities of detergent to each pod. This level of precision eliminates inconsistencies that can occur in manual processes, reducing the likelihood of product rejection and rework. Accurate dosing also ensures that pods maintain consistent weight and performance, which is essential for brand reliability and customer satisfaction.

High-Speed Operation

Production speed is a critical factor in overall efficiency. Traditional semi-manual methods are limited by human labor capacity and are susceptible to bottlenecks at various stages. High-speed detergent pod making machines overcome these limitations by performing multiple operations simultaneously and continuously.

Advanced machines can produce hundreds or thousands of pods per hour, depending on their configuration and capacity. This high-speed operation allows manufacturers to meet growing market demand while reducing production cycle times. Combined with precise dosing and sealing, high-speed machines maintain quality even at large volumes, providing both efficiency and reliability.

Minimized Material Waste

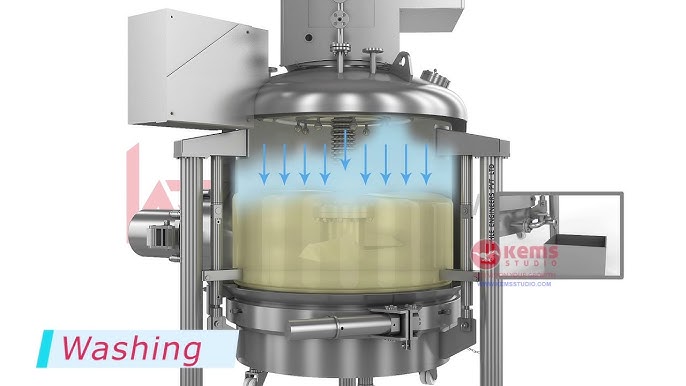

Material waste is a common challenge in detergent pod production. Incorrect dosing, film misalignment, or sealing errors can lead to defective pods that must be discarded, increasing operational costs.

Detergent pod making machines address these issues through precise film handling systems, automated sealing mechanisms, and real-time monitoring. Sensors detect misaligned film, improperly sealed pods, or other anomalies, allowing operators to take corrective action immediately. By reducing waste, manufacturers can optimize raw material usage, lower production costs, and improve overall operational efficiency.

Flexible Production Capabilities

Efficiency is not only about speed but also about the ability to adapt to varying production requirements. Modern detergent pod making machines are designed with flexibility in mind, capable of producing different pod sizes, shapes, and multi-chamber formulations.

This adaptability allows manufacturers to switch between products without lengthy machine reconfigurations. For example, a single machine can produce standard detergent pods for everyday use, premium multi-chamber pods with fabric softener, or pods with specialized fragrance profiles. This flexibility reduces downtime during product changeovers and enables manufacturers to respond quickly to market trends, enhancing overall production efficiency.

Integrated Monitoring and Maintenance

Regular maintenance and monitoring are crucial for maintaining efficiency in any production environment. Detergent pod making machines are often equipped with sensors, alarms, and automated diagnostics that track operational performance in real time.

These systems alert operators to potential issues, such as worn components, blockages, or misaligned film, before they cause significant downtime. Preventive maintenance guided by real-time monitoring extends machine life, ensures consistent pod quality, and minimizes unplanned interruptions, all of which contribute to greater production efficiency.

Conclusion

Detergent pod making machines improve production efficiency through automation, accurate dosing, high-speed operation, minimized material waste, and flexible production capabilities. By integrating real-time monitoring and preventive maintenance, these machines ensure reliable performance, consistent product quality, and reduced operational costs.

Investing in a modern Detergent Pod Making Machine enables manufacturers to scale production, optimize resource usage, and maintain a competitive edge in the growing laundry pod market. By leveraging these machines’ efficiency-enhancing features, businesses can meet increasing demand while maintaining quality and profitability.