As consumer awareness of environmental and social issues grows, sustainable and ethical practices in yoga leggings manufacturing have become essential. The activewear industry, including yoga leggings, can have a significant environmental footprint due to fabric production, chemical use, and energy consumption. Ethical practices also ensure fair labor conditions, promoting social responsibility alongside sustainability. By adopting these practices, manufacturers can create high-quality products while reducing environmental impact and supporting workers’ rights.

Sustainable Material Sourcing

One of the key components of sustainable yoga leggings manufacturing is the use of eco-friendly materials. Recycled polyester, regenerated nylon, organic cotton, bamboo, and Tencel are commonly used by forward-thinking manufacturers. These fabrics minimize the reliance on virgin resources and reduce textile waste. Recycled fibers, for example, are often made from post-consumer plastics or production scraps, diverting waste from landfills and oceans. A reputable Yoga Leggings Manufacturers carefully selects materials that meet performance, durability, and sustainability standards, ensuring that the leggings provide comfort and stretch without compromising the environment.

Ethical Labor Practices

Sustainable manufacturing is closely linked with ethical labor practices. Responsible yoga leggings manufacturers ensure safe working conditions, fair wages, and respect for workers’ rights. Compliance with international labor standards, such as fair trade certifications, helps prevent exploitation and promotes equitable treatment throughout the supply chain. Brands that prioritize ethical practices benefit from stronger consumer trust and loyalty, as buyers increasingly demand transparency and accountability in the products they purchase.

Energy-Efficient and Low-Impact Production

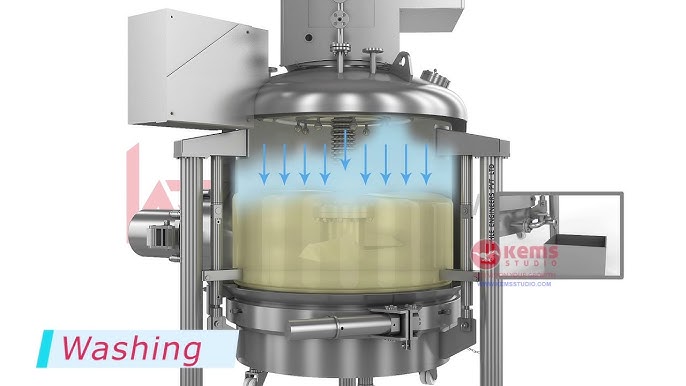

Minimizing energy consumption and environmental impact during manufacturing is another critical practice. Advanced machinery, optimized workflows, and renewable energy sources reduce the carbon footprint of production. Techniques such as waterless dyeing, low-impact color processes, and chemical-free finishing help prevent pollution while maintaining vibrant and durable leggings. By investing in cleaner production methods, yoga leggings manufacturers contribute to the reduction of greenhouse gas emissions and water waste in the textile industry.

Waste Reduction and Circular Practices

Waste management is an integral part of sustainable yoga leggings manufacturing. Manufacturers are implementing strategies to reduce scrap fabric, reuse offcuts, and recycle defective products. Circular practices, such as take-back programs, allow consumers to return old leggings for recycling or repurposing into new garments. These measures decrease landfill waste and extend the lifecycle of materials, reinforcing sustainability while aligning with consumer demand for environmentally responsible products.

Quality Control for Longevity

Durability is an important aspect of sustainability. High-quality yoga leggings that withstand frequent wear and washing reduce the need for replacement, lowering overall consumption. Manufacturers focus on precision stitching, reinforced seams, and fabric testing to ensure that leggings maintain shape, elasticity, and color over time. By producing long-lasting garments, yoga leggings manufacturers reduce environmental impact while providing better value to consumers.

Eco-Friendly Packaging

Sustainable practices extend beyond the garment itself to packaging and shipping. Manufacturers are increasingly using recycled or compostable packaging, plant-based mailers, and minimalistic designs to reduce waste. Eco-friendly packaging demonstrates a commitment to sustainability and enhances the overall brand image. Some manufacturers also implement reusable packaging options, encouraging consumers to participate in waste reduction initiatives.

Transparency and Certifications

Transparency in sourcing and production is a key factor for ethical and sustainable practices. Certifications such as OEKO-TEX, Global Organic Textile Standard (GOTS), and Fair Trade provide assurance that fabrics and manufacturing processes adhere to environmental and ethical standards. By sharing certifications and supply chain information, manufacturers allow brands and consumers to make informed choices, fostering trust and accountability within the yoga wear industry.

Innovation and Sustainable Design

Innovation plays a significant role in promoting sustainability. Yoga leggings manufacturers are exploring advanced fabrics, seamless knitting technologies, and performance-enhancing treatments that reduce environmental impact. Eco-friendly dyes, moisture-wicking finishes, and durable stitching techniques ensure that leggings are both high-performing and sustainable. These innovations reflect a commitment to continuous improvement in environmental and social responsibility.

Conclusion

Sustainable and ethical practices in yoga leggings manufacturing are essential for reducing environmental impact and promoting fair labor conditions. From eco-friendly materials and energy-efficient production to circular practices, transparent supply chains, and durable design, manufacturers are shaping a responsible and innovative industry. By choosing ethically produced and sustainable leggings, consumers support practices that protect the environment and ensure social responsibility. Partnering with reliable yoga leggings manufacturers that prioritize sustainability allows brands to deliver high-quality, long-lasting, and eco-conscious products to the market, reflecting a growing demand for responsible activewear.